Vero Software Release VISI 2016 R1 WWW.VISI2016R1.COM

Significant developments in CAD, Mould and CAM functionality are included in VISI 2016 R1, from Vero Software. The product naming convention also explains the move to a new 6 month release cycle with two versions planned per year.

As a leading developer and provider of CAD/CAM/CAE solutions, Vero Software say VISI 2016 R1 is a substantial release introducing many new features in all areas of the product with continued emphasis on solutions for mould, tool and die makers.

Major graphic enhancements include an updated GUI with quick access toolbars, live icon combinations on the mouse, improved hidden line removal and geometry selection by ‘free-shape’ brush. In addition, CAD translators have been updated to support the latest 3rd party CAD formats including Inventor 2016, layer categories for NX and attribute hole mapping for Catia V5.

User efficiency continues to be a focus for product development and major CAD developments include significant picking and sketching enhancements, associativity improvements for 3D dimensions, a re-designed part revision manager, and multiple plotview updates.

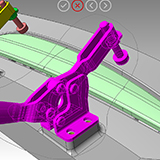

VISI Mould developments include improved cooling channel management with support for solid groups, CAD transformations and updated catalogue components such as plugs, connectors and baffles. Additional enhancements include a new tool to produce lubrication grooves and a re-written database tool to manage and edit the 3D standard element libraries.

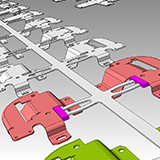

For those involved in sheet metal stamping, VISI Progress updates include improvements to the part replacement for 3D strip design, the ability to manage multiple strip designs within the same project, and the option for defining families of punches as instances; allowing for automatic updates of geometry if the parent punch is modified.

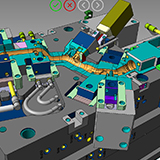

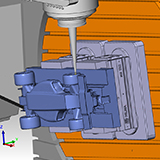

VISI 2016 R1 represents another release with major CAM developments covering 2D, 3D milling, and wire EDM updates. 2D enhancements include significant speed improvements (especially on complex patterns), a final clearance milling path for zig-zag toolpaths and improved linking for pocketing operations. For 3D machining operations, the user interface has been simplified to help define the geometry piece, stock and additional faces. An updated CAM engine provides better memory management and improved performance allowing VISI to run multithreads for a single toolpath calculation. This means that a single toolpath build can be split into parallel calculations, significantly reducing the total build time (this is managed automatically by the CAM engine). Wire EDM developments include 64Bit engine support, improved 4-axis offset support, and feature recognition for constant tapered apertures.

Other CAM developments include improved analytic material removal, updated stock/model comparison, and a new ‘toolpath enquirer’ tool to allow the operator to analyse the underlying toolpath data and search for geometry such as elements shorter than a given length or vertical arcs.

For more detailed product information, please visit: