Dynamic Design

Founded in March 2007, and located in Cazzago St. Martin, Brescia, Dynamic Srl operate in a number of industry sectors ranging from heating, ventilating and air conditioning through to automotive. However, Dynamic have also developed a reputation as experts in the development and production of compression and injection moulds for indoor and outdoor furniture. The company provides moulds for major brands such as Origlia, Casprini, Bonaldo and Miniform amongst others.

Due to the higher mechanical strengths and excellent surface finish required for furniture, Dynamic specialise in the use of gas assisted moulding with BMC (bulk moulding compound) and SMC (sheet moulding compound) glass fibre reinforced polymer resins. Furniture part thickness can vary greatly so gas assisted moulding permits the use of thin and thick sections to ensure structural integrity of the product without the risk of sink marks or unpredictable distortion and warpage. The principle of gas assisted moulding is that nitrogen gas is injected during the moulding cycle. The major benefits are the elimination of sink marks and the creation of a cavity voids without the need of a core insert. During the cooling phase of normal injection mould tools, the moulding will shrink away from the cavity and an extra pack of material has to be introduced to counteract the sink. When using gas assisted moulding this additional pack is replaced by nitrogen which helps eliminate sink marks and improves overall surface finish.

"We will continue to search for advanced technology and are certain that the Vero products will be an integral part of our success.”

Tiziano Perini

"Most of the designers who come to us asking to make their models a reality, start with a prototype in wood" explains Ivano Muratori, Project Manager at Dynamic Srl. "One of the major tasks is to translate this information into a CAD environment. Typically we make a point to point scan of the prototype and rebuild the model using complex surface data."

RECONSTRUCTION OF GEOMETRY

Obviously, the CAD reconstruction must be faithful to the original prototype but there is often a compromise between product design and production feasibility. It is important to understand the technical requirements of the model which is influenced by the geometric shape, the selected material and the moulding technology. Balancing the requirements of product design and production technology is usually a significant challenge.

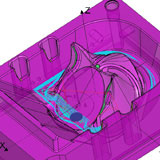

Dynamic has been using the VISI product suite from Vero Software for two years. "We expected a lot from the products and we haven't been disappointed" claims Muratori. "We are able to create to complex prototype geometry using VISI Modelling, the plastic flow analysis using VISI Flow and the production tooling using VISI Mould and Vero's MACHINING STRATEGIST. The integrated nature of the product ensures there are no data translation issues when moving between departments."

PROTOTYPE AND FEASIBILITY STUDIES

After geometry reconstruction, a resin prototype is produced by milling the complete model from a rough block which is subsequently submitted to the designer for evaluation. Simultaneously to prototype production, a series of feasibility studies are carried out on the mould production and part geometry using VISI Flow. The results of hot runner simulations and cooling channel analysis are all carried through to the mould design.

"What's really important" continues Muratori, "is that the results on the press exactly match the results provided by VISI Flow. This allows us to monitor and fine-tune our technological processes."

"For us VISI Flow is a very important tool on which we rely heavily. It allows us to reduce the number of samples which ultimately saves us time, and the customer money. We have a good working relationship with the Vero engineers and have received regular product customisations that further extends the product, creating an even closer fit to our needs. If we discover a defect on the first batch of plastic parts, we are able to run multiple simulations searching for the optimum solution. For example, changing the viscosity of the material without having to supply the full material characteristics is a very important point and translates into significant time and cost savings for us."

CAM

The cost of a mould often accounts for 30 / 40% of the entire project costs and within this the manufacturing stage is a significant cost - It is imperative to eliminate bad decisions during this phase of construction. Tiziano Perini, CEO of Dynamic explains the benefits of switching to MACHINING STRATEGIST from their previous CAM system. "We decided to move to the Vero CAM system because of its simplicity and calculation speed. Every time we create a new toolpath, it is automatically distributed to the other multi threading processors making maximum use of the PC power. As soon as our technicians were trained, they were immediately productive and confident with the output."

TIME SAVING

With the introduction of the Vero products at Dynamic, the technology processes have evolved but most importantly, the time frame from design conception through to final part production has been reduced by 50%. "We can now guarantee project completion within 6 months when previously it took us almost a year" explains Tiziano, "We have halved our production time which in the current economic climate has proved to be a major advantage".

Concluding, Tiziano Perini explains, "In the near future we plan to increase the number of moulding presses and make further investments in the moulding department. We will continue to search for advanced technology and are certain that the Vero products will be an integral part of our success."

About The Company:

Name: Dynamic Srl

Web: www.dynamic-italia.it

Benefits Achieved:

- Accurate surface construction from wooden prototype

- 50% reduction in total project life cycle

- Software simulation matching the real life moulding conditions

"We will continue to search for advanced technology and are certain that the Vero products will be an integral part of our success.”

Tiziano Perini