VISI - A Winning Formula

The use of VISI, from Vero Software for machining Titanium and other exotic hard-to-cut materials keeps Formtech GmbH, a Bavarian high-tech mould and toolmaker, racing ahead with its Formula 1 motorsport clients.

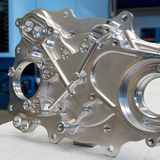

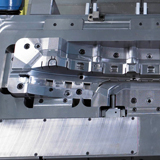

Based in Niederwinkling near Straubing, Formtech GmbH was established in the 1990s producing complex mould tools, supplying around 100 new tools a year. However, Managing Director Franz Hilmer says that today, half of their 7- million Euro turnover comes from machining high-precision components for a range of prestigious clients, including a number of big-name Formula 1 teams such as Force India F1, Sauber F1 and Williams F1.

“We couldn’t operate efficiently without the advantages of the 3D CAD functions, which are closely aligned to our mould construction processes, or without VISI’s automated link to the CAM operations."

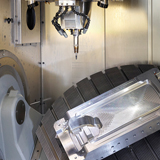

Operations Manager Florian Radlbeck says a main production focus is manufacturing high precision Titanium components using a combination of 17 CNC centres from DMG, Hermle, Matsuura (with work-piece palettes) and an OPS production cell for producing graphite electrodes. More than ten of the CNC machines are capable of running simultaneous 5-axes operations, although 3+2 is sufficient for most production tasks.

All NC programming is performed using VISI Machining, with two additional workstations running VISI Modelling and VISI Analysis for 3D tool design, model preparation for manufacture and electrode production. The latest software module from the Vero product suite to be added was a license of VISI PEPS-Wire, for both 2D and 4-axes wire EDM operations.

By standardising on the use of VISI, this ensures data consistency and interoperability from 3D CAD, tool design through to CAM production. The innovative machining strategies within VISI are an integral and essential part of Formtech’s success. Florian Radlbeck says they would not be able to mill Titanium economically without them. As well as Titanium Ti6A14V, Formtech also machine other hard-to-cut materials such as aluminium alloys, unhardened and hardened case-hardened steel, tool steel and graphite for electrodes. These difficult-to-cut metals, along with special aluminium alloys, are supplied by sister company Formtech Advanced Materials GmbH, which was founded to guarantee the consistent supply of these high-grade materials in such a competitive and highly demanding industry sector.

Florian Radlbeck explains: “When working with Titanium, we typically use a combination of the Matsuura machines, which are best suited for the job due to their rigidity, and also special milling strategies. This is where VISI's adaptive tool paths come into play. These adaptive tool paths remove the material using a high speed, trochoidal motion when moving into areas of full width cuts. We also benefit from utilising the full length of the cutting tool, with tool wear spread evenly across the cutting surfaces, reducing deflection and the potential for vibration, improving cutting conditions and allowing higher machining speeds to be maintained.”

Formtech also utilises state-of-the-art technology to manufacture their electrodes. They are produced using a multi-shift operation on both HSC machines from OPS, which automatically shifts the pallets containing the finished electrodes and the electrodes which are still to be milled. “The milling programmes for the electrodes, are of course, also produced using VISI”, claims Radlbeck.

Because VISI is so easy to use, their machine operators are also the CAM programmers. “While the machine is milling, the operator uses VISI to create the NC programs and strategies for the next task, saving a great deal of time and ensuring optimum flexibility as they are closest to the action.” Six CAM workstations are installed next to the CNC machines where all of the milling programs are produced. “We’ve had positive results using this procedure across our whole spectrum of work.”

Concluding, Florian Radlbeck says Formtech works exclusively with VISI because the software provides their complete CAD/CAM solution. “We couldn't operate efficiently without the advantages of the 3D CAD functions, which are closely aligned to our mould construction processes, or without VISI’s automated link to the CAM operations. This ensures not only better processing times, but also greater flexibility. VISI's innovative milling strategies mean that even the most complex parts can be manufactured to an accuracy of one hundredth of a millimetre. This is prized just as much in the automotive industry as it is within Formula 1.” - And that’s an important consideration for Formtech, as they also provide prototype production services to the automotive industry, in particular BMW and Volkswagen.

About The Company:

Name: Formtech GmbH

Business: Toolmaker & Production Machining Specialists

Benefits Achieved

- VISI ensures data consistency and interoperability from 3D CAD, tool design through to CAM production

- While the machine is milling, the operator uses VISI to create the NC programs and strategies for the next task.

- Improved tool life using adaptive tool paths which utilise the full length of the cutting tool and remove the material using a high speed, trochoidal motion.

Comments:

“We couldn’t operate efficiently without the advantages of the 3D CAD functions, which are closely aligned to our mould construction processes, or without VISI’s automated link to the CAM operations.”

Florian RadlbeckOperations Manager