Turbo-Charged Stamping Tool Production

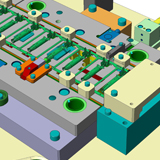

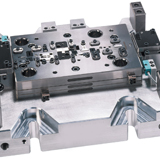

An important part of a German subcontractor’s success is its in-house tool production. Kleiner Stanztechnik GmbH produces more than 60 highly complex progressive forming tools a year. And since switching to VISI for 3D tool design, Kleiner now has an integrated process chain based on 3D data, covering everything from quotations, through to design and NC programming.

Combining extensive experience of high-performance stamping tools and precision stampings with new technologies and developments, Kleiner manufactures parts for the automotive, plastics, electrical, medical technology and electronics industries. Kleiner operate Bruderer and Haulick & Ross presses running up to 1,200 strokes per minute, and can process strips with a width of up to 320 mm and a thickness of 0.06 to 4 mm on 38 hydraulic presses with a pressing force of up to 250 tonnes. The product portfolio extends from micro-stampings to populated lead frames, which replace the commonly used printed circuit board. An example of their expertise in complex precision stamped parts are snap domes with spots of gold for buttons and switches. The small amount of gold used by the spot galvanisation delivers an immediate cost saving.

"We were immediately comfortable with the design process, not just because it’s extremely easy to use, but because the special modules for stamping tool design were already well established in the market and the software gave an impression of being well-engineered."

Ego Kugele, Head of Design

In the field of renewable energy and electric mobility, Kleiner offers solutions for high current contacting of hybrid and electric vehicles’ photovoltaic systems. A recent example of this is plug coupling for charging electric cars, in which Kleiner designed and manufactured electrical contact elements in the signal and high voltage areas. This included replacing the plug connectors, originally designed as turned copper components, with stamped parts.

As well as the electrical and insulation design, the challenge had been to optimise the geometry of the parts in such a way that they could be produced easily with a progressive tool, which Kleiner also design and manufacture. “We design new projects exclusively in 3D using VISI, which is tailor-made for our type of work,” says Head of Design Ego Kugele.

Around three years ago an increasing workload prompted them to improve on their existing system for faster tool design. That, coupled with the fact that they needed a more advanced system to handle circuit boards and functions for the strip layout, meant that design switched exclusively to 3D, through VISI. “We originally trialled a fully parametric system, but the system constraints we not very suitable for efficient tool design. We subsequently trialled VISI and were immediately comfortable with the design process, not just because it's extremely easy to use, but because the special modules for stamping tool design were already well established in the market and the software gave an impression of being well-engineered,” explains Ego Kugele.

The company which is based in Pforzheim, Germany, now has VISI Modelling and the cutting and stamping tool module VISI Progress, for processing, strip layout and tool construction, installed on 14 workstations in the design department, along with one other workstation used for quotations. There are three further VISI Machining installations in the production department for programming the milling machines.

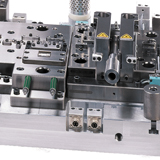

Once the tool design is complete, manufacturing begins with all programs created using VISI Machining (with the addition of VISI-PEPS Wire for 2 and 4 axes planned for later in 2013) for the Agie and Hurco CNC machines. A third VISI Machining workstation is used to drive a high speed Röders machine dedicated to hard milling and the manufacture of copper electrodes. The CAM operator prepares all NC programs offline so the machine can be used to produce multiple jobs at the same time. And since the same CAD model is used in VISI for design and NC programming, integration and interoperability of the data is always guaranteed.

Two VISI workstations include the automatic feature recognition module, Compass Technology for processing and automatically applying approved, company standard toolpath data to common geometric features such as multi-depth holes and open and closed pockets. The introduction of Compass Technology has dramatically reduced the programming time by more than 60% for certain 2D and 2.5D milling tasks on complex bolster sets.

Concluding, Frank Chojinski, a member of the Management Board, says: “We are continuously investing in our staff, in new technology and in optimising our processes. We deliberately focus on high innovative stamping technology, together with the tools required for it.” And he says that with VISI, the more delicate and complex the job, the more they like it.

About The Company:

Name: Kleiner Stanztechnik GmbH

Web: www.kleiner-gmbh.de/

Benefits Achieved:

- The same CAD model is used for design and NC programming. Therefore, integration and interoperability of the data is always guaranteed.

- Compass Technology has dramatically reduced the programming time by more than 60% for certain 2D and 2.5D milling tasks on complex bolster sets.

- Kleiner now has an integrated process chain based on 3D data, covering everything from quotations, through to design and NC programming.