Prodir - A pen that flows

Prodir, a Swiss company based in Canton Ticino specialize in the manufacture of customised pens and writing instruments for use as advertising media. Since the start of 2010, Prodir has been working closely with DesignworksUSA, a creative consulting firm belonging to the Munich-based BMW Group for all of the main new products for 2010 and 2011 including the ES1 and the new CS8 Pen-Books which have already won the 2011 edition of the “Promotional Gift Award”, a major European industry award. The Prodir promotional writing instruments belong to a new generation of environmentally-friendly products which are synonymous with Switzerland’s environmental policies and Prodir’s tag line, “Personality pens. Swiss made”.

All Prodir writing instruments, and components, from the tip to the cap parts are manufactured entirely in Switzerland with a R&D laboratory at the headquarters in Novazzano for material research and colour development. According to Prodi, the appearance is of fundamental importance in the development of a pen. The design work should be studied in minute detail, taking into account issues related to differences in thickness, shape and form.

"To survive over time, a promotional product must be well made with excellent design and high writing quality. To achieve this goal we can never have enough ideas and are constantly striving to improve with the help of specialist software. It is certainly true that VISI Flow has helped us in this direction.”

Sergio Ravasi

Accurate analysis before designing the mould

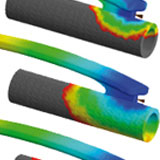

To optimize the injection moulding phase, Prodir designers use VISI Flow, plastic flow simulation from Vero Software. Antonio Primerano, designer at Prodir explains, “We use the software to provide accurate analysis at the design stage when the cost of changes are still minimal and before any steel is cut. We use the analysis to identify and solve a range of issues including weld lines, air traps and best gate location, all which were traditionally linked to the experience of the moulder.”

“Using VISI Flow we have been able to reduce production times by a month, a remarkable result considering that the time frame from product development to delivery and marketing takes approximately six - seven months.”

An example of the benefits of using VISI Flow can be highlighted during the development of the DS2 cap model. “In this case, we had a problem during the moulding of a component with a crossbow clip. VISI Flow successfully simulated the filling problem and we were able to predict the benefits of moving the gate position. The analysis also showed that the warpage could be improved by changing the injection pressure and injection time. With these counter measures now in place, we have eliminated the moulding issues and the part is correctly produced.”

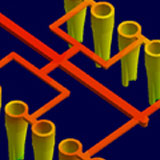

“For new projects, we typically perform 5-6 simulations for each pen using VISI Flow” continues Antonio Primerano. “This allows us to start the initial phase with confidence. Our mouldings are often small and we must pay special attention to the placement of the gating positions which must be located so that it is hidden once the pen is assembled. The feeding sites must be as small as possible to be almost invisible, but at the same time, it must have a diameter large enough to allow you to inject the correct amount of plastic to ensure the proper filling of the part.”

One important ecological prerequisite for Prodir is the need to eliminate plastic agglomerate to reduce waste. Sergio Ravasi, Production Manager explains, “80% of our waste material is re-used for internal processes. However, due to material degradation and colour reduction, 20% of waste no longer meets the quality requirements set by the company and is sent to companies who specialise in plastic recycling. In this sense, we use VISI Flow extensively to accurately simulate the plastic behaviour in the nozzle to inject directly in four parts and eliminate agglomerate pieces.”

A large database of polymers

Using a proprietary hybrid mesh, VISI Flow is able to calculate the 3D simulation of the plastic flow front in a very short time. The approach of the proprietary technology ensures consistent results regardless of the size of the geometry, its complexity or the distribution of thickness. The accuracy of the analysis results are directly related to the characterization of the material. VISI Flow includes an extensive database of materials covering a wide range of polymers divided by area and supplier. Prodir pens are typically produced using ABS (transparent to opaque, which in turn are divided into matt and gloss ) for both the body and internal mechanisms. Behind every pen, there is a large study of materials with colours accurately matched to the thickness of the various details. In addition to the five basic colours, it is possible to choose any PMS colour for the body, ensuring the highest level of customisation.

Concluding, Sergio Ravasi explains the benefit of innovative technology. “The Prodir pens are products of high level design, shape and material. The quality is very important to us and is a strong differentiator to the competition. To survive over time, a promotional product must be well made with excellent design and high writing quality. To achieve this goal we can never have enough ideas and are constantly striving to improve with the help of specialist software. It is certainly true that VISI Flow has helped us in this direction.”

About The Company:

Name:Prodir

Benefits Achieved:

- Provide accurate analysis at the design stage when the cost of changes are still minimal and before any steel is cut

- Savings of more than a month of production time on each project

"To survive over time, a promotional product must be well made with excellent design and high writing quality. To achieve this goal we can never have enough ideas and are constantly striving to improve with the help of specialist software. It is certainly true that VISI Flow has helped us in this direction.”

Sergio Ravasi