VISI Key For Toolmaker Expansion

Using the VISI suite of CAD/CAM applications from Vero Software significantly reduces the overall costs of each project for a German toolmaker, and makes it easier to implement innovative design ideas.

Based in Velbert, Volker Gehlen Werkzeugbau GmbH have a 30 year history of providing innovative solutions for stamping and forming industries. They are going from strength to strength, with the acquisition of a stamped component manufacturing company, acquiring new machines, and the addition of new products to their range.

“VISI makes it significantly easier for us to implement ideas; and as tool optimisations can be made much quicker, this significantly reduces the overall cost of projects for our clients.”

Volker Gehlen, Director

Managing Director Volker Gehlen says a vital factor in their success has been upgrading all CAD/CAM operations to VISI’s integrated 3D tool making solution. It was the software’s consistent operating philosophy for CAD and CAM that initially made it a front-runner when they were looking to change. “We made the final decision after a trial installation and training from VISI’s German reseller Mecadat AG. VISI proved to be so easy to operate, and can be used so intuitively that it was giving us a high level of efficiency after only a few days.”

The company’s turnkey solutions to customers throughout Europe include technological advice, prototype construction, and tried and tested full suites of tools. And he says VISI software helps them stay at the top of their game. “We’ve invested heavily in CAD/CAM and use VISI exclusively to design our tools. We can’t imagine doing it any other way now.”

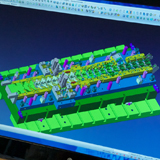

Three designers each have a workstation equipped with VISI Modelling, and the stamping die module VISI Progress for strip layout and 3D tool construction. Lukas Gehlen, who is in charge of design and production, says: “The hybrid modelling combines a Parasolid kernel with surface modelling, giving us a faster and more flexible workflow that can handle any geometry type.”

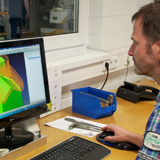

Two additional workstations feature VISI Modelling and 3D Machining to provide NC programs for the company’s four Hurco and DMU CNC milling machine. A more recent software addition is the VISI PEPS-Wire licence to support the generation of NC programs for three state-of-the-art Sodick wire eroders – one of which is the AQ 1200 L, able to process metal more than four-and-a-half feet wide, weighing up to four tons.

Other software modules include VISI Compass for manufacturing automation, which uses preset processing definitions to create automatic NC programs for feature based drilling, milling and wire erosion geometries. Finally, the shop floor runs VISI Viewer for checking CAD models in a paperless environment to verify where each component fits.

However, he says they offer much more than just high quality tools. “We support our customers from the original idea right through to the finished product. And VISI plays a key role at the start of that process, by helping us carry out a feasibility study and 3D evaluation to confirm in the early stages that the parts will function correctly.”

VISI is also used to edit 3D CAD data supplied by customers, which is then transferred to their ProJet HD3500 3D printer. This produces fully functioning, fit for purpose, acrylate components up to 300mm, hardened by UV light, for prototypes and pre-series parts. “We can print entire assemblies, including moving parts, with a maximum size deviation of 0.2 per cent, at a thickness of 10 µ. If a pre-series is ordered, we 3D print first, so the customer can test it in terms of size, form and function. Then we supply the first 50 metal parts, so the client is able to fully test the form and fit during the development stage without having to pay for costly prototype tools and modifications.”

Their traditional tool making and stamped part production has also been strengthened with the purchase of a 200-ton press. The high-tech machine has a servo drive giving a flexible adaptation of the ram speed and acceleration, producing 60 per cent more parts in the same time, while still saving power. “We can test and optimise the newly developed tools under realistic production conditions, providing the customer with a proven tool that can be used immediately.”

Lukas Gehlen concludes: “Overall, we use VISI to design and produce our tools much more efficiently, and we are able to react with more flexibly to customer requirements.” He says being able to seamlessly import data into the VISI core modeller means there are no problems with customers’ files, which saves a tremendous amount of time compared to how long projects used to take. “VISI makes it significantly easier for us to implement ideas; and as tool optimisations can be made much quicker, this significantly reduces the overall cost of projects for our clients.”

Three designers each have a workstation equipped with VISI Modelling, and the stamping die module VISI Progress for strip layout and 3D tool construction. Lukas Gehlen, who is in charge of design and production, says: “The hybrid modelling combines a Parasolid kernel with surface modelling, giving us a faster and more flexible workflow that can handle any geometry type.”

Two additional workstations feature VISI Modelling and 3D Machining to provide NC programs for the company’s four Hurco and DMU CNC milling machine. A more recent software addition is the VISI PEPS-Wire licence to support the generation of NC programs for three state-of-the-art Sodick wire eroders – one of which is the AQ 1200 L, able to process metal more than four-and-a-half feet wide, weighing up to four tons.

Other software modules include VISI Compass for manufacturing automation, which uses preset processing definitions to create automatic NC programs for feature based drilling, milling and wire erosion geometries. Finally, the shop floor runs VISI Viewer for checking CAD models in a paperless environment to verify where each component fits.

However, he says they offer much more than just high quality tools. “We support our customers from the original idea right through to the finished product. And VISI plays a key role at the start of that process, by helping us carry out a feasibility study and 3D evaluation to confirm in the early stages that the parts will function correctly.”

VISI is also used to edit 3D CAD data supplied by customers, which is then transferred to their ProJet HD3500 3D printer. This produces fully functioning, fit for purpose, acrylate components up to 300mm, hardened by UV light, for prototypes and pre-series parts. “We can print entire assemblies, including moving parts, with a maximum size deviation of 0.2 per cent, at a thickness of 10 µ. If a pre-series is ordered, we 3D print first, so the customer can test it in terms of size, form and function. Then we supply the first 50 metal parts, so the client is able to fully test the form and fit during the development stage without having to pay for costly prototype tools and modifications.”

Their traditional tool making and stamped part production has also been strengthened with the purchase of a 200-ton press. The high-tech machine has a servo drive giving a flexible adaptation of the ram speed and acceleration, producing 60 per cent more parts in the same time, while still saving power. “We can test and optimise the newly developed tools under realistic production conditions, providing the customer with a proven tool that can be used immediately.”

Lukas Gehlen concludes: “Overall, we use VISI to design and produce our tools much more efficiently, and we are able to react with more flexibly to customer requirements.” He says being able to seamlessly import data into the VISI core modeller means there are no problems with customers’ files, which saves a tremendous amount of time compared to how long projects used to take. “VISI makes it significantly easier for us to implement ideas; and as tool optimisations can be made much quicker, this significantly reduces the overall cost of projects for our clients.”

About the Company

Name: Volker Gehlen Werkzeugbau GmbH

Web: www.volkergehlen.de

Benefits Achieved

- Single product solution to develop products faster, and innovate more efficiently.

- VISI Modelling used to edit customer CAD data, which is then transferred to the ProJet HD3500 3D printer.

- VISI Machining and VISI PEPS-Wire used to drive the HURCO, DMU and Sodick CNC machines.

- Improved tool optimisation, significantly reducing project costs for clients.

Comments

“VISI makes it significantly easier for us to implement ideas; and as tool optimisations can be made much quicker, this significantly reduces the overall cost of projects for our clients.”

Volker Gehlen, Managing Director