VISI - Much More Than Moulding CAD/CAM

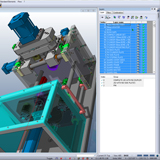

One of the UK’s leading injection moulding specialists for the engineering and industrial sectors uses VISI software for much more than designing mould tools. Rutland Plastics, using their Objet 3D printer, designed and manufactured a secondary operation jig which halved the manpower required for the shop floor assembly.

"Any good engineer can see it’s not just a CAD/CAM system for creating injection moulding tools; it’s an extremely powerful system for anything in the design world.”Carl Martin, Technical Manager

Technical Manager Carl Martin says: “Any good engineer can see it’s not just a CAD/CAM system for creating injection moulding tools; it’s an extremely powerful system for anything in the design world. We use it for designing a number of different items throughout the business, from a small jig, through to a complete multi-impression mould tool.”

He says VISI’s role in ensuring the company could competitively produce a pipe coupling for the drainage industry is an example of its versatility. “We used VISI to create a 3D printed prototype of the coupling, the mould tool for production, and a unique jig to automate a manual part of the operation.”

Carl Martin says the mesh functionality within VISI was a useful tool when preparing the model geometry for printing on the Objet Connex 350. The mesh feature set provides tools to clean-up problematic vertices, simplify, fill holes and analyse the mesh topology. Printing a fit-for-purpose prototype meant the customer could fit prototype physical model to the pipes, ensuring it functioned as expected, before having the mould tool built. “It’s expensive to change tooling if the moulded part isn’t correct. The 3D printed part worked perfectly, so we then moved forward with building the injection mould tool in VISI.”

As the part had already been designed in VISI, it was a seamless CAD through CAM process to manufacture the mould in P20 hardened tool steel. VISI Mould’s essential model preparation tools inspect the model data for moulding feasibility, while draft analysis interrogates the model to easily identify any potential design issues. “We used the split line and plane creation function for the two cavities, and then built up the ancillaries around that to design the tool as a whole. It meant we could be sure of the accuracy of each individual aspect – namely the cavity plates, the backing plate, the ejector system, the risers and the clamping plates.”

Another important aspect was how VISI Flow’s injection simulation showed optimum moulding conditions by identifying and the ideal locating gate positions. “It was vital for us to verify where the part needed to be gated, which areas may be difficult to fill, and where venting needed to be placed into the tool. VISI Flow showed us how the tool would perform on the moulding machine.”

The High Density Polyethylene (HDPE) component links two pieces of pipe by electrofusion, using special fittings that have built-in electric heating elements which are used to weld the joint together. In order to be successfully welded in the field, brass continuity pins have to be inserted before the part is shipped out of the factory. “Originally we had one operator managing the turning and wire laying, with a second person manually inserting the pins which hold the wire in place.” Automating the pinning process and reducing manpower from two to one was essential for Rutland Plastics to remain competitive. “

"We used VISI to design the jig to handle this job, from the ground up. VISI created the components and animated all movements showing how it would function on the shop floor.”

The suite of VISI in use at Rutland also includes VISI PEPS-Wire, VISI Electrode and VISI Machining 3D, which play an equally vital role in the production process, programming two Bridgeport VMC mills, a Fanuc Robocut 1ia wire eroder and a AgieCharmilles Roboform 30

spark eroder.

“With around 90 per cent of moulded products requiring textured finishes, we often use spark erosion. If a customer requires a certain VDI spark finish we design an electrode in VISI, bring our back-end Erowa block into the system and get it to the point at which it needs to be placed on the machine. It’s then manufactured on either the lathes or mills, and the form sparked in to give us the specified finish.” With electrode production being time consuming and complex, this

VISI module easily creates and manages electrodes and their holders for detailed and hard-to-machine features. Comprehensive holder design, simulation and collision checking ensures the electrode will be perfect first time.

VISI PEPS-Wire is used where small, intricate inserts need to be wired into the mould tool. It provides automatic recognition of wire features from solid geometry, creating reliable wire EDM toolpaths and proven

NC code.

Once the tools are built, Rutland Plastics’ use their range of Engel and Krauss Maffei injection moulding machines to produce a variety of components for the gas, water and petrochemical industries, agricultural products, electrical enclosures, the construction industry and automotive. Marketing Manager Stuart Lovett says: “The moulding operation runs 24 hours a day over a five-day week, manufacturing anything from just a few grams in weight, right up to a 710 mm electrofusion coupler weighing 48 kilos, which is our largest product.”

Although focusing on the mould tool itself, rather than part design, Rutland Plastics use VISI to assist customers in ensuring their parts are suitable for injection moulding. As with the electrofusion pipe coupling, prototypes are often 3D printed on the Objet, with its 350 x 350 x 200 mm build tray, which also forms the basis of their 3D printing bureau service. He expects 3D printing to become increasingly popular for one-offs and small batch numbers, as the Objet can print ten different materials in any one run, and a total of 110 materials overall.

About the Company

Name: Rutland Plastics

Web: www.rutlandplastics.co.uk

Benefits Achieved

- VISI used to create a 3D printed prototype, the production mould tool, and a unique jig to automate assembly operations.

- VISI Flow used to identify where parts needed to be gated, which areas may be difficult to fill, and where venting needed to be placed into the tool.

- VISI PEPS-Wire, VISI Electrode and VISI Machining 3D used to program Bridgeport VMC mills, Fanuc Robocut 1ia wire eroder and a AgieCharmilles Roboform 30 spark eroder.

Comments

Any good engineer can see it’s not just a CAD/CAM system for creating injection moulding tools; it’s an extremely powerful system for anything in the design world.”

Carl Martin, Technical Manager