VISI 2017 R2

VISI 2017 R2 provides new and enhanced functionalities for both CAD and CAM processes, specifically designed for the mould and die market.

New Springback | CAD

When the sheet metal part is removed from the die, and the forming forces released, material elasticity will cause the part geometry to experience springback. The new Springback prediction functionality is designed to reduce the time and cost of a typical trial and error approach to solving this long-standing industry issue.

The Springback prediction tool uses the starting nominal part, material data and blank calculation to generate a second mesh of the product geometry including springback adjustments. The designer can then use the relative compensation tool to achieve a morphing on the original surface set to generate the compensated surfaces to produce an accurate sheet metal part. This will provide major benefits to the die market by reducing the time of the ‘design to manufacturing’ process and by reducing the cost of a typical trial and error approach to solving this long-standing industry issue.

New Safety zone visualisation | CAD

When a designer is validating the part for formability, a new graphical analysis representation mode will subdivide the results into six possible zones that occur during the forming process:

Strong Wrinkle Tendency - Slight stretch in one direction and compression in the other with material thickening. Wrinkles are very likely to occur.

Wrinkling Tendency - Stretch in one direction and compression in the other with slight material. thickening. Wrinkles may occur.

Low Strain - Minimal stretch or compression in either the major or minor directions.

Safe - Area below Forming Limit Curve where failure is not likely to occur.

Marginal - Area between the safe and fail zones where the forming process is marginally safe.

Fail - Area above Forming Limit Curve where splitting is likely to occur (localized thinning).

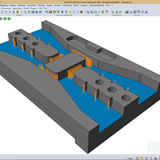

2.5 Axis Pocketing | CAM

The new 2.5 Axis Pocketing strategy provides toolpath quality improvements, an optimised toolpath on open features (shorter toolpath) and provides the ability to machine from a stock model. When the stock model is defined the new Pocketing strategy is able to identify the areas where it is necessary to remove the material and adapt the toolpath to produce passes only where necessary.

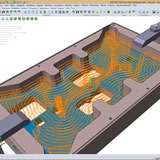

2.5 Axis Waveform | CAM

The new 2.5 Axis Waveform strategy (previously available in 3D roughing), delivers high speed machining technology to maintain constant tool cutting load, constant cutting feed rate, and smooth toolpath movements which avoid sharp changes in direction which maintains the machine tool’s velocity.

2.5 Axis Remachining | CAM

The new remachining strategy, based on the new Pocketing technology, inherits the same enhancements and advantages provided by the Pocketing strategy. The rest area recognition is achieved automatically based upon the reference operations selected. The computation of the rest material is using a new computation engine that is shared with 3 Axis CAM strategies.

3 Axis Enhanced Roughing - Remachining | CAM

The enhancements achieved on the Roughing and Remachining strategy provides a more reliable and higher quality toolpath. The residual material algorithm has been enhanced to provide a better quality residual area output. The result is an improved toolpath quality and an optimised toolpath in reference to the residual area computation.

New Electrode Machining | CAM

The new Electrode machining module automates the electrode design-to-manufacturing process. It benefits from collecting the manufacturing information added during the design phase, and automatically passing the data to the CAM cycles. This will significantly speed up the process of electrode manufacture and reduce the potential risk of possible input error.

As there are often a substantial number of electrodes required to be machined for each mould, the new Electrode machining module delivers major time saving benefits for the mould production.

Other important enhancements introduced in the latest VISI 2017 R2 release are:

- New Product Launcher which is a customisable software starting window which provides access to the complete suite of installed VISI applications. The launcher also has dedicated areas for the users most commonly used tools which can be added by drag & drop, as well as displaying the VISI social media channels.

- Improved user experience with high quality toolbars to support 4k monitors

- Updated CAD translators to support the latest geometry formats

- Improved Wire EDM technology and software fixes