VISI Flow Demonstrates Injection Simulation and Controlled Warping at Plastics Exhibition

Vero Software will showcase how precise the injection simulation results are for its VISI Flow rheology module, starting from filling through to warpage estimation phases, at the FIP Plastic Solutions Trade Fair in Lyons.

The show is unique in France, with over 800 exhibitors demonstrating their role in the development of plastic and composite parts, which Samantha Mayet, Vero’s Marketing Coordinator for France, says makes it perfect for featuring VISI Flow.

“VISI Flow is a unique plastic injection simulation tool, ideal for pre- and post-production analysis whatever the size, thickness or complexity of the part.”

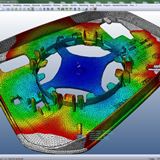

Its wide range of features allows the analysis of variables such as pressure, temperature, shearing, solidified thickness, and fibre orientation. Users can simulate/test the reliability of their injection process from filling through to estimating warpage while, at the same time, controlling the thermal aspects of the mould.

“Enhancements within the filling and holding algorithms in the latest release have increased the precision of warpage calculations. The goal has been to enhance the reliability of the simulation results with respect to the final shape of the part thus avoiding multiple and costly test phases.”

The warped model geometry can then be compared with the original geometry for retro design requirements, or to model counter-warping requirements.

The show runs from June 13 – 16 at the Lyon Eurexpo. Vero is sharing a 27 square metre booth, B2, with Sematec Metrologie and Hexagon Manufacturing Intelligence.